The examples below indicate the types of defects VISPER can detect.

Copper exposure |

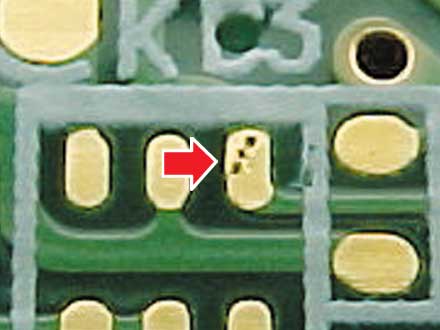

Foreign material |

Copper exposure |

Scratch on solder resist |

Solder mask discoloration |

Component marking defect |

Component marking defect |

PCB crack |

Flux in the |

V-Cut missing |